ANZINE : CAE 기술 매거진

이전 ANZINE Home New Product

Introduction of a curve fitting tool to identify material constants of Visco-elastic material models

- Koji Yamamoto

- CYBERNET SYSTEMS CO.,LTD.

- marketing@tsne.co,kr

Introduction of a curve fitting tool to identify material constants of

Visco-elastic material models.

Koji Yamamoto | CYBERNET SYSTEMS CO.,LTD.

■ Abstract

최근 신뢰성 향상을 위한 요구가 증가하고 있고, 이를 해결하기 위한 방안 중 하나인 재료의 비선형 거동을 고려한 해석에 대한 이슈가 많아지고 있다. 이러한 추세에 맞추어 비선형 재료 모델 중 점탄성 재료 모델의 상수 값을 효율적으로 도출할 수 있도록 새로운 Curve fitting Tool을 소개한다. 이는 DMA Raw 데이터를 기반으로 한 마스터 커브 생성, Shift Function 상수 식별, 그리고 Prony 계열 점탄성 모델을 통한 상수 값 도출의 3단계 과정을 통해 점탄성 재료의 특성을 자동으로 추출하여 해석에 적용할 수 있게 만들어 준다. 이를 통하여 사용자에 따른 재료상수의 적용 오차 및 숙련도에 따른 Fitting 시간을 줄일 수 있다. 특히 PMMA와 에폭시 수지를 대상으로 한 적용 사례를 통하여 Tool의 유연성과 정확도를 확인할 수 있다. 이 Curve Fitting Tool을 활용하면, 온도 의존성을 갖는 점탄성 재료의 물성을 CAE해석에 적용하여 제품 신뢰성 평가 업무에 크게 기여할 것으로 기대된다.

Introduction

In recent years, we have been receiving an increasing number of inquiries regarding analyses that consider the nonlinear behavior of materials such as resins. We believe that the purpose behind this is to use CAE to examine the application of new materials and the high demand to improve long-term reliability, which is triggered by the need to realize a sustainable society. However, it is also true that the use of CAE for nonlinear problems can present some stumbling blocks in the early stages of the analysis study, the best example being the preparation of material property values. Although there are established methods for experimentally obtained material behavior, especially for viscoelastic problems, and Ansys® software has provided such analysis functions for a long time, the curve fitting function for obtaining physical property values have the following problems.

a. Raw data from dynamic viscoelasticity tests cannot be utilized.

b. Time-temperature conversion law (namely shift function) is not supported.

c. There is an upper bound on the number of elements that make up the generalized Maxwell model.

This required users to go through the trouble of secondary processing of material test data to meet the specifications of the physical property identification function, as well as technical know-how to compensate for the lack of functionality. To solve these problems, we have developed a tool to identify the physical properties of viscoelastic materials in a versatile and easy way with the cooperation of Nihon University. This paper presents an overview of its functionality.

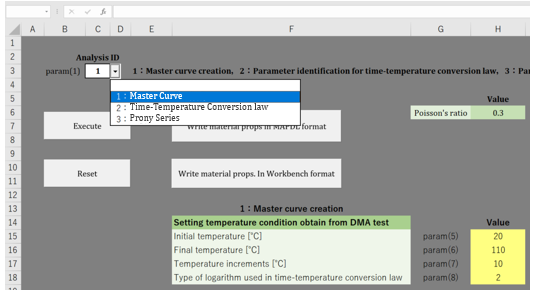

Figure 1: Appearance of the viscoelastic curve fitting tool, provided as a feature of Multiscale.SimTM[3]

a multi-scale analysis and simulation software developed by CYBERNET SYSTEMS CO., LTD.

■ For Material Property Identification System for Viscoelastic Models

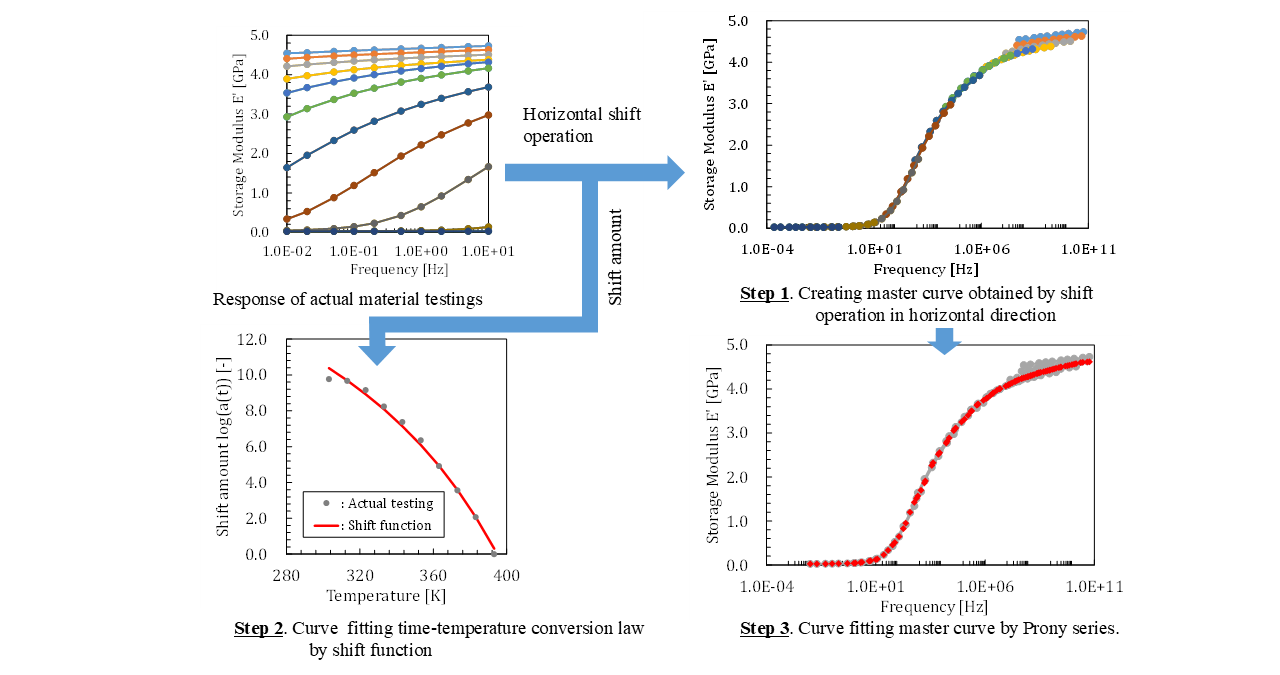

A material model is always required to represent the material behavior in functional form to account for nonlinear material behavior in the analysis. Material models in structural problems mainly express the relationship between stress and strain as a function with several coefficients (material constants). Differences in material behavior are expressed by those coefficient values. To accurately reflect material behavior in the analysis, it is necessary to actually observe the material behavior in tests and adjust the material constants that make up the material model to match. The tool presented here accomplishes these tasks through the three steps shown in Figure 2.

Figure 2: Ansys flow to identify material constants for Visco-elasticity.

■ Step 1: Creating a master curve

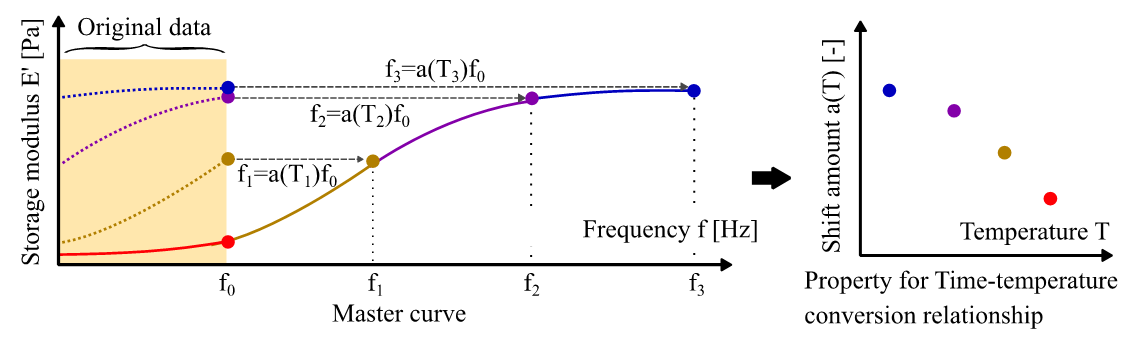

Since it is difficult to directly measure material behavior over long periods of time, viscoelastic material behavior is usually measured by unique test which name is Dynamic Mechanical Analysis (DMA), in which cyclic variable loads are applied with different temperatures. An image of this test is shown in Figure 3. For materials including viscous characteristic, a phase difference between stress and strain occurs, so the material behavior is expressed by decomposing the elastic modulus into an in-phase component E'' and a dissimilar component E''. In DMA, the frequency band that can be loaded is limited, and accelerated tests at varying temperatures are required to obtain characteristics over a wide frequency range. For thermorheologically simple viscoelastic materials, temperature changes can be matched to changes in frequency (or time). This characteristic is called the time-temperature conversion law. This feature allows us to virtually obtain material behavior over a wide frequency range at a specific temperature by taking multiple temperature levels, even for limited frequency range tests. The task of converting temperature to frequency corresponds to the operation of translating the frequency-dependent elastic modulus along the horizontal axis, as shown in Figure 4. This shifting operation is performed for each temperature to derive a single connected curve, or master curve.

Figure 3: Schematic diagram to explain Dynamic Mechanical Analysis (DMA) test.

Figure 4: Operation to identification material properties of time-temperature conversion law.

■ Step 2: Identification of material constants for time-temperature conversion law

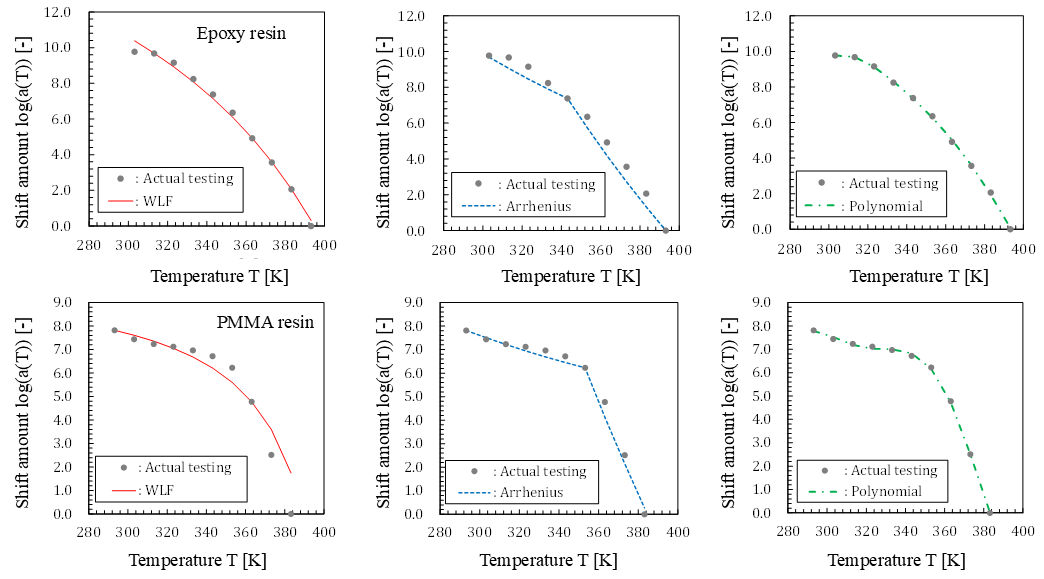

The amount of shift must also be represented as a material model called a shift function. An example of actual curve fitting using the responses of PMMA and epoxy resins in the three functional forms provided by this tool is shown in Figure 5. If the characteristics change discontinuously around the glass transition point, as in the case of PMMA resin, the reproducibility by WLF is poor. The polynomial form provides the most rigorous fitting of experimental data, but it also allows to have fitting of small experimental errors and thus carries the risk of overlearning. Thus, the optimal shift function to use depends on the type of resin. This tool provides a rich set of shift functions and robust curve fitting capabilities, allowing the temperature-dependent behavior of a wide variety of resins to be reflected in the analysis in a versatile and easy manner.

Figure 5: Example of the curve fitting results for epoxy and PMMA resins. Our tool provides three types of models.

■ Step 3: Identification of material constants of the Prony series

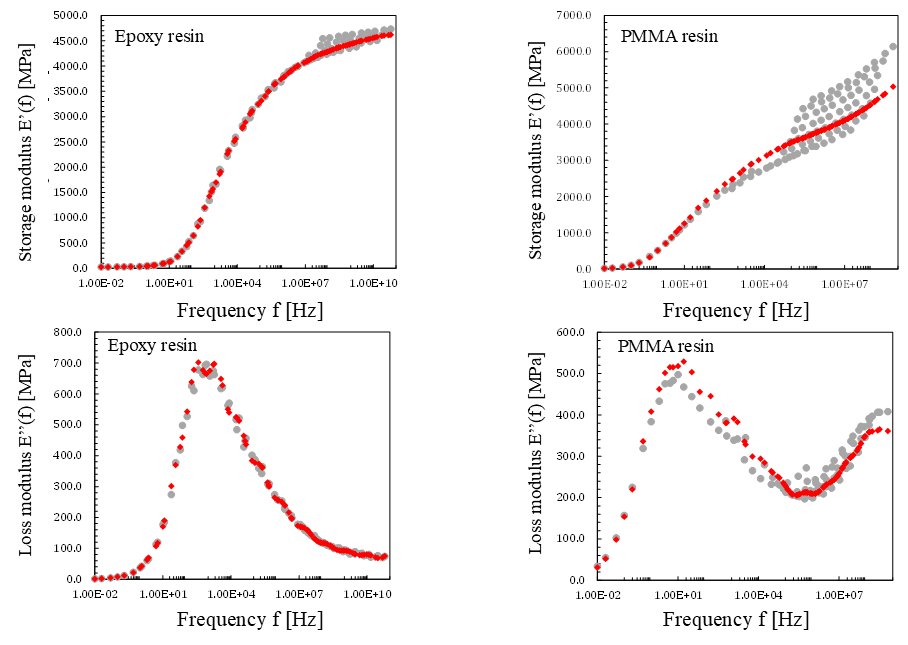

Finally, the master curve obtained by the shift operation of the time-temperature conversion law is fitted by a viscoelastic material model called the Prony series[1]. Our tool allows direct fitting of storage modulus E' and loss modulus E'' obtained by DMA without any limitation on the number of Maxwell elements. Figure 6 shows the master curve fitting results for the epoxy and PMMA resins mentioned in the previous section. Curve fitting results against PMMA resin is not exactly on the master curve obtained from DMA test data on the low temperature side (high frequency side). This is because PMMA resin has a strong temperature dependence not only on the viscous term of material properties but also on the elastic term, which shifts in the direction of the elastic modulus axis. To accurately describe this phenomenon, it is necessary to introduce the concept of a new time-temperature conversion law[2]. The corresponding functionality will be implemented in a future version of the software.

Figure 6: Curve fitting results based on the master curve obtained from DMA actual testing data of epoxy and PMMA resin.

The number of Maxwell element is set larger than 22 which is upper limit of Ansys standard feature.

Conclusion

In this article, we introduced the new analysis tool to identify material constants of Visco-elastic problems. As part of our efforts to improve product reliability, we expect that the level and responsiveness required of CAE will become more and more demanding in the future. We would be very happy if the tools described in this paper could contribute to the efficiency of this work.

■ References

[1] ANSYS, Inc. online help, Materials Reference, Viscoelasticity Formulations.

[2] K. Yamamoto et al, Numerical study on the relaxation properties and temperature dependence of elastic modulus in anisotropic viscoelastic constitutive law of fiber-reinforced thermoplastic resin, Transactions of the Japan Society of Mechanical Engineers, Vol. 85, (2019).

[3] https://www.cybernet.co.jp/ansys/product/multiscale/en/multiscale/

■ About CYBERNET

CYBERNET is a leading digital engineering solutions company established in 1985 and headquartered in Tokyo, Japan. Its corporate slogan is "Making the world more convenient and richer through the unlimited possibilities of people and advanced technology." CYBERNET is an Apex Channel Partner and a Technology Partner (Software) of Ansys. The company has been developing Multiscale.Sim since 2007, and it is used by many customers in Japan and around the world.

For more information :

- Visit: www.cybernet.co.jp/ansys/product/lineup/multiscale/en/

- Email: cmas@cybernet.co.jp

㈜태성에스엔이

㈜태성에스엔이