ANZINE : CAE 기술 매거진

이전 ANZINE Home Case Study

[Global] A world on water #2

- Livio Furlan

- EnginSoft

- l.furlan@enginsoft.com

물 위의 세계

A world on water #2

Livio Furlan, EnginSoft

Published in Futurities Year 21 n°1 by EnginSoft

■ Abstract

바다는 열에너지의 잠재적 원천으로 주목받기 시작했으며, 해저 퇴적물은 풍부한 광물 자원과 탄화수소의 보고(寶庫)입니다. 현재 해양 석유와 가스는 전 세계 에너지 수요의 약 3분의 1을 차지하고 있습니다. 이러한 흐름에 발맞춰 해양 건설 산업은 해양 자원 개발을 위한 구조물 설치에 주력해왔습니다. 막대한 경제적 가치를 지닌 해양 석유 및 가스 산업은 관련 기술의 빠른 발전을 이끌었고, 이를 통해 인간의 창의성과 기술력은 극한의 환경에서도 놀라운 공학적 성과를 이루어냈습니다. 본 기고에서는 그 대표적인 두 가지 사례를 통해 이를 살펴보고자 합니다.

바다 위에 작은 ‘세계’를 세우는 일은 과학적이고 체계적인 접근 없이는 불가능합니다. 정밀하고 안전한 설계를 위해서는 끊임없는 연구와 실천, 끈기, 신중함, 열정, 그리고 창의성이 조화를 이루어야 합니다. 이러한 요소들이 균형을 이룰 때 비로소 하나의 구조물이 완성되는 진정한 ‘성공’이 실현될 수 있을 것입니다.

오늘날 인공지능이 인간을 대체할 수 있다는 전망이 나오고 있지만, 여전히 새로운 아이디어를 구상하고 실현하는 일은 인간의 몫입니다. 해양 설계가 이루어질 환경과 조건을 철저히 이해하는 전문 팀이 구성된다면, 지금까지 인류가 그래왔듯, 다양한 위험 요소와 복합적인 상황에 효과적으로 대응할 수 있을 것입니다.

▶ A world on water #1

A bit of history…

Since before recorded history, the seas were sailed in conquests and used for transport, to provide food, and to dispose of waste borne by the rivers along which various civilizations built their villages and cities.

The Phoenicians sailed as far as Norway in the north and Cape Town in the south – perhaps even as far as South America; the Polynesians crossed the Pacific sighting the great wall of the Andes on one side, which they marked as the “end of the world”, and Japan and Indonesia on the other; while the Kerala’s navigators reached Africa and Indonesia thereby completing primitive man's circumnavigation of the globe. Modern nautical “knowledge” is largely based on the accumulated experience of all these navigators. Nonetheless, it is a science that sits at the crossroads between several disciplines, specifically astronomy, geography, and meteorology, as well as the use and application of measuring and observational instruments. Later came the Arab sailors whose maritime empire stretched from West Africa to the Philippines; the Vikings, who sailed as far afield as Canada, Greece and North Africa; and finally, the Western European navigators during the Age of Exploration, who braved the remotest corners of the globe, including both the Arctic and the Antarctic.

In addition to being a vast resource of food, since the second half of the last century oceans have also been definitively recognized as a potential source of thermal energy, although Ocean Thermal Energy Conversion (OTEC) projects while technically feasible are not yet economically viable.

Also since the second half of the 20th century the oceans and their sediments have been fully recognized as a major source of mineral wealth and hydrocarbons to the extent that offshore oil and gas still provide almost one-third of the world's energy needs.

More recently, in addition to the immense publicity given to manganese nodules covering vast areas of the tropical and subtropical seabed, the scientific world was excited by the discovery in the rifts of the seafloor of hot springs, their strange new life forms, and their deposits seemingly rich in polysulphide minerals.

Minerals – salt, trivially – have been extracted from the sea since prehistoric times whereas, in modern times, magnesium and bromine have been extracted from coastal sediments rich in deposits of precious minerals such as gold, tin and, probably, chromium and platinum.

However, most recent maritime construction activity has focused on the installation of structures to meet the needs of the oil industry due to the enormous economic importance of offshore oil and gas and consequently of developing technology for its exploitation.

■ The contractual aspects and development phases of offshore projects

Many offshore projects therefore concern the extraction of marine resources recognizable as oil and gas. The sovereign nation with jurisdiction grants leases for the exploitation of deposits in specific offshore areas to an oil company, with corresponding provisions for royalties and taxes, and for the development of operations. The concession may involve specific agreements concerning possible alliances with other companies and/or contractors, training and employment of local people during construction, mandated use of local manufacturers and suppliers and the local purchase of materials, and research activities to benefit the grantor nation.

Once it has the lease in hand, the operating oil company conducts extensive geophysical and seismic surveys, and it is during this phase that it drills surface cores to obtain bathymetric data and environmental information. Typically, floating vessels, drill ships and/or semi-submersibles are used for exploratory drilling in deep offshore waters, while jack-ups are used in shallower areas.

If the presence of a reservoir is confirmed by these exploratory surveys, the oil company performs delineation drilling to determine the actual characteristics and extent of the reservoir. While gathering more accurate and site-specific geotechnical and environmental data for use in the design and intensifying its planning operations for the offshore development, the oil company simultaneously conducts feasibility and preliminary engineering studies to select a concept for the offshore structure and identify potential contractor tenderers.

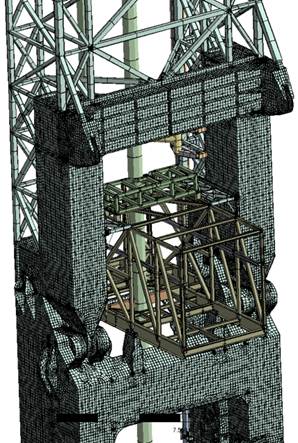

Fig.1. Finite element models of a portion of a J-launch tower (left), and a Bell-Mouth (right)

The position of operator is highly sought after by oil companies as it confers control of the project, along with substantial fees to cover operating and general costs in most cases. In addition, this role allows the company to develop in-house engineering expertise and advanced management skills. Once the project is approved, the operator proceeds to finalize contracts for the construction and installation of the offshore platform. In many cases, these contracts cover the following phases:

· substructure design,

· deck design,

· substructure construction,

· purchase of process equipment,

· construction of the deck and its preparation for equipment installation,

· substructure installation,

· deck installation,

· connection offshore,

· production drilling.

Many of these phases are combined into logical groups (Engineering, Procurement, Construction – EPC) before being awarded to a single contractor.

Pipelines are used to transport the crude oil or liquid by-products from extraction/ production sites to loading ports, from unloading ports to refineries, and from refineries to shipping ports for the finished products.

The following activities are related to this aspect:

· submarine pipeline design,

· pipeline procurement,

· pipeline lining,

· pipeline installation, possibly involving the digging of trenches to support the pipelines to ensure their stability.

A crucial activity in pipeline installation at sea concerns the design and construction of the laying equipment.

Shallow and/or medium depth waters require an S-launch configuration using Stinger, which is a lattice launching ramp positioned at the stern of the installation vessel (e.g. Saipem's Castoro 6 or CastorONE). The pipeline is progressively built inside this vessel and then runs along these ramps into the sea.

In deep water, a J-launch configuration is used. It consists of actual towers equipped with appropriate equipment to progressively fabricate the pipeline to be laid that are installed on the deck of the launch vessel (e.g. Saipem's SSCV S7000). The J-launch configuration also features a Bell-Mouth lattice structure at the exit point of the pipeline from the launch to prevent its over-bending.

The J-launch tower, Bell-Mouth (or Flute), and Stinger are among the offshore structures that can be classified as fixed (as they are tied to the vessels on which they are installed) and, as such, can be designed/ sized (a description of the design phases of a fixed offshore structure is provided in part two of this article).

Obviously, the actions induced by waves and currents (on the Stinger and Bell-Mouth); the forces transmitted by the pipeline during launch; and the inertial forces generated by the surge, sway, heave, roll, pitch and yaw of the vessel during launch must be considered when designing these structures. The surge, sway, heave, roll, pitch, and yaw motions are characterized by the RAOs (Response Amplitude Operators) typical of each vessel.

While on the topic of Flute, in 2014 EnginSoft collaborated intensively with De Pretto Industrie on its engineering development. Built by De Pretto Industrie, the Flute was to be installed beneath the

J-launch tower of the S7000, along the launch line of pipelines to be laid on the bed of the Black Sea for the South Stream Project (see the article published in the EnginSoft Newsletter, issue 3, 2015).

After installation, drilling begins from the platform. In many cases, production begins after a few wells have been completed while drilling for other wells continues. Once all the wells are operational, periodic workovers are necessary to ensure their continued productivity.

As mentioned previously, most oil and essentially all gas shipments (deliveries) are made via pipelines to a coastal terminal. Some of the gas is, however, retained and used on board the platform to fuel its operation. Oil can also be shipped via tankers. In this case, a subsea pipeline runs from the platform to a loading buoy for direct transfer, via a rotating header, to a tanker moored at the buoy.

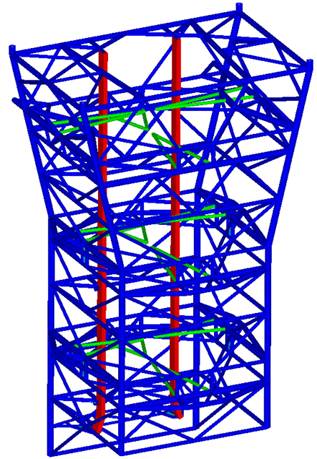

This is the case of the Vega field, located approximately 12 miles south of the southern coast of Sicily, off the coast of Pozzallo. In 2012 and 2013 on behalf of Susanna Donà’s engineering studio, EnginSoft assessed the extension of the operational life of the Single Point Mooring (SPM) by creating finite element models of the column, the universal joint, the triaxial joint and the hinge joints (see Fig. 2) after which associated numerical analyses were undertaken to determine the stress field distributions in order to calculate the fatigue damage using the deterministic approach.

During a platform's operational life, maintenance, repairs, and modifications (brown field activities) are required. Although these are usually relatively minor operations compared to those in the green field (i.e. during new design, construction, and installation), they are often just as demanding in terms of technical skills and specialized equipment.

Regulations in most countries state that when a reservoir/field has reached the end of its operational/economical life (usually after 20-30 or even 40 years), all structures are to be removed (decommissioned) and the wells are closed and sealed with cement.

The need to transform unprofitable or decommissioned facilities (assets) can be viewed as an opportunity to give them a new lease of life: decommissioning creates employment and the chance to regenerate raw materials and assets that have reached the end of their original industrial life cycle but that still have potential for reconversion and reuse in other initiatives. For example, some offshore structures, after reaching the end of their life due to the depletion of deposits, can be redeveloped as facilities to start up offshore marine science parks, or as facilities for environmental monitoring, or for use in renewable energy, or potentially even converted into hotels, sports centres, or diving resorts.

Fig. 2. Finite element models of the parts of a single point mooring (SPM).

■ The interaction between design and construction

The installation of an offshore structure requires feasibility studies, planning, preparation and, eventually, execution. Generally grouped under the term” construction”, these operations involve many design-related activities, including engineering, all of which must all include an appropriate degree of sophistication/detail. Once completed, the structure is required to function adequately under normal service conditions, but it must also safely withstand extreme environmental events and foreseeable accidents. This means that the structure must not suffer progressive collapse as a result of earthquakes, impact from icebergs, extreme storms or even ship collisions. It must also withstand the repeated loads typical of the marine environment, considering that an offshore platform can undergo, for example, up to 200,000,000 or more wave load cycles during its operational life.

Careful consideration of the numerous construction requirements and their interaction with design, regulatory requirements, the environment, logistics, economics, time, risk, and reliability led to the development of the concept of “constructibility”, a term to describe an evolving process that lasts for many years. Constructability denotes a continuously progressing framework that has a specific input at each phase of an offshore project, from conception to maintenance, and from repair to eventual life extension and removal.

Thus, it can be said that the demands and challenges of offshore construction, be it for the production of hydrocarbons or green energy, make it one of the most exciting fields of engineering which tests the ability to reach new levels of skill and commitment.

■ Physical-environmental aspects of maritime and offshore construction

The oceans present a unique set of environmental conditions that determine the methods, equipment, support, and procedures to be employed in offshore construction. This same unique environment, of course, also dominates design. The following is a brief description of the main environmental factors that act simultaneously, and which therefore must be considered in the development of an offshore facility project, whether destined for use for oil and/or gas extraction or dedicated to the production of green energy (wind power).

■ Depth

The average depth of the oceans is about 4,000m, with the maximum depth being over 10,000m (which is deeper than Everest rises above sea level). Constructions have already been conducted at depths of 1,500m, exploratory oil drilling operations at 6,000m, and offshore mining tests at similar water depths. Ocean depths, even the “common” levels at which many offshore facilities are located, are inhospitable and mostly dark and therefore require special equipment, tools, and procedures for location, control, and communication. Innovative technologies were developed to meet these needs: specific work submarines, remotely operated vehicles (ROVs), fibre optics, and acoustic imaging.

Depth is associated with hydrostatic pressure and thus it is important to recognize the limits that depth still imposes on phenomena of unstable equilibrium which can induce the instantaneous and unfortunately dramatic collapse of submerged structures.

Hydrostatic pressure is a function of depth according to the well-known linear law:

p= ρ g h

where:

· p is the pressure (force per unit area)

· ρ is the density of seawater,

· g is the acceleration of gravity

· h is the depth.

The pressure is obviously influenced by wave action: hydrostatic pressure is determined by the elevation of the crest of the wave itself and is greater than the pressure directly below the wave hollow. This effect diminishes with depth: for waves of moderate height the effect becomes negligible after depths of 100m, for storm waves the effect becomes negligible after depths of 200m.

Hydrostatic pressure is related to the concept of buoyancy: a body immersed in a fluid experiences a bottom-up thrust equal in value to the weight of the fluid volume displaced (Archimedes' principle). In the case of a submerged object, its net weight in water can also be thought of as the difference (or closed integral) of the hydrostatic pressures acting on its surfaces.

■ Currents

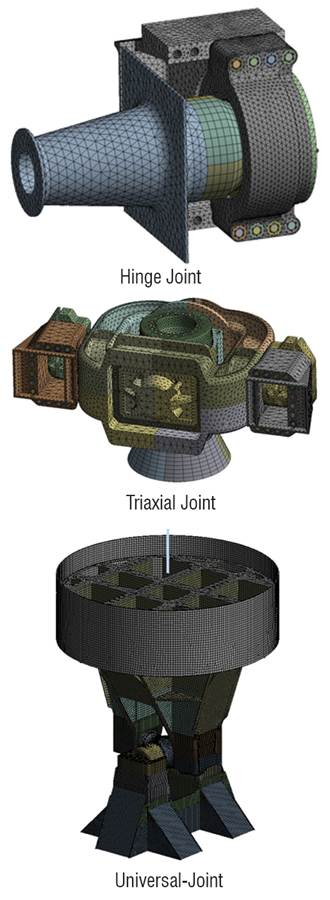

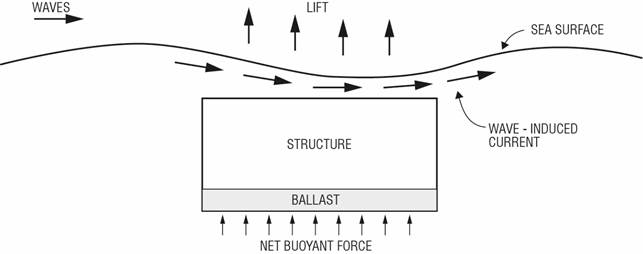

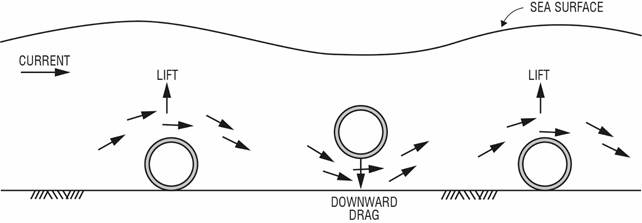

Currents, even small ones, have a significant effect on marine operations and offshore construction. They affect the movement of ships and the response of floating structures and moorings, change wave characteristics, exert pressure on structural surfaces and, due to the Bernoulli effect, develop uplift or drag forces on horizontal surfaces (Fig. 3 and Fig. 4). They also create eddies around structures, which can lead to runoff and soil erosion (Fig. 4).

When sea currents run over poles, cables and/or moorings, and pipes (conductors, risers, etc.), a vortex shedding phenomenon may occur, which must be evaluated carefully. In fact, if the frequency of vortex shedding is close to a frequency resonance condition, it produces greater amplitudes of oscillation when the damping and mass of the structure or element are lower.

Fig. 3. The “beach effect” - uplift forces on a shallowly immersed structure due to wave-induced current.

Fig. 4. Oscillating movement of seafloor pipeline due to current.

The vertical profile of currents is conventionally shown as decreasing with depth in a parabolic function. Indeed, recent studies on deep-water projects indicate that in many cases the velocities of stationary currents just above the seabed are almost as high as those closer to the surface.

One important source of currents can be found in tidal changes. The strongest tidal currents usually occur close to the coastline but can extend for a considerable distance offshore where they are channelled by underground reefs or by bathymetry.

Although they generally follow the tidal cycle, tidal currents often lag an hour behind the tide that generated them; thus, a tidal current may continue to flood the surface for a short period after the tide has begun to recede.

Pressure acting on a surface normal to the direction of the current velocity varies with the square of the velocity. Considering that current velocity is superimposed on the orbital velocity of the wave particles, significant drag force effects may occur with pressure resulting in a force proportional to the square of the vector sum of the velocities.

■ Waves

Waves are the biggest environmental problem for offshore structures and related marine operations. They cause floating structures or ships to respond in the six degrees of freedom (surge, sway, heave, roll, pitch, yaw), thus putting significant strain on all their parts. In marine operations, they can also be the main cause of downtime and reduced operational efficiency. Therefore, for fixed structures, wave forces are generally the dominant design context.

Waves are mainly caused by the action of wind on the water which transfers its energy to the surface layer of the sea through friction. Waves occur when the water is still under the action of the wind. Once these same waves have moved beyond the wind-affected zone as a result of distance or time, they are called swells. Waves and swells can be predicted based on knowledge of the winds. For this purpose, routine forecasts are available for several offshore operational areas. A wave is effectively a travelling disturbance of the sea’s surface. The disturbance travels but the water particles within the wave move in an almost closed elliptical orbit with little distinct forward motion. The height of a wave is determined by wind speed, duration, and fetch (the distance travelled by the wind over the open sea).

The total energy of a wave is proportional to the square of its height. While the height of the wave is an important parameter, the period of the wave can be just as important particularly for marine operations. Long-period waves have a great deal of energy, for instance when the length of a moored ship is less than half the length of the wave that sweeps over it, the vessel will experience significant dynamic forces. Waves vary considerably and even simultaneously within a site. Therefore, they are generally characterized by their significant height (Hs) and significant period. The significant height of a wave is the average height of the highest third of waves. If a strong wind lasts less than a minimum duration the wave height will be proportional to the square root of the duration. A sudden gale therefore will not be able to blow up much of the sea.

So-called deep-sea waves tend to travel in groups with a series of higher waves followed by a series of lower waves. The speed of the group of waves is about half the speed of the individual waves.

This means that technicians can wait for of a period of low waves following the higher waves before carrying out some critical, rapid construction operations such as placing a load on a deck or driving a pole.

Average wave height is about 0.63Hs. Only 10% of waves have a height greater than Hs and only one wave in one thousand has a height greater than 1.86Hs; this is often considered the maximum wave height although recent studies show that the value may be closer to 2. Wave height H is the vertical distance between crest and cable and T is the period (i.e. the time elapsed between the passage of one crest and the next over the same point). Wavelength L is the horizontal distance between two crests. Velocity V (often called celerity C) is the speed of propagation of the wave.

Approximate relationships exist between these factors:

L=1.56 T2

T=0.8 √L

V=L/T

Seas are often a combination of local wind waves from one direction and swells from another. Swells from a storm at the site may overlap with swells that are running out ahead of a second storm that is still hundreds of miles away. The result will be confused seas with occasional waves and pyramidal troughs.

■ Winds

As we have seen, wind is the main cause of wave formation on the sea surface, but as an atmospheric agent it also directly affects the parts of the offshore structure above the water, generating forces on them that are a function of the square of the wind speed as well as the extent of the exposed surfaces. Wind speed increases as one rises above sea level. For example, the wind at a height of 20m may be 10% greater than at a height of 10m (which is the usual reference height for defining the design value of wind speed). Near sea level, wave friction greatly decreases the speed.

Winds are not constant but blow in gusts: a three-second gust, for example, can be one third to one half as fast as the average of the same storm over an hour.

The predominant pattern of oceanic winds is driven by air circulation around the permanent areas of high pressure that cover the ocean, which is clockwise in the northern (boreal) hemisphere and counter- clockwise in the southern (austral) hemisphere.

In tropical and subtropical zones, extreme heat and the interplay between the atmosphere and the ocean create deep pressure lows that generate violent storms. These are known as tropical cyclones in the Indian Ocean, the Arabian Sea, and off Australia; hurricanes in the Atlantic and South Pacific; and typhoons in the Western Pacific.

The occurrence of such storms in subtropical and temperate zones is seasonal, from late summer to early autumn, and fortunately still quite rare. In many areas of the world adjacent to dry land, masses of cold high-pressure air can accumulate on land and then suddenly rush out over the sea, generating winds of 100km/h or more (even up to 150– 180km/h). Since these winds do not have a long duration, usually lasting only a few hours, the seas are not fully developed and therefore the waves are short and steep.

■ Tides

Tides are the result of the gravitational attraction of the moon and the sun. Due to their relative mass and distance, the sun exerts only half the influence of the moon on the tides. The highest tidal ranges occur during new and full moons, when the sun, earth and moon are roughly in line; these are called spring tides.

When the positions of the sun and moon form a 90° angle to the earth, i.e. the moon is in the first or third quarter, the tidal ranges are lower; these are called neap tides.

The depth of the sea shown on the charts usually refers to the mean lower low water (MLLW) which is the average low tide height during spring tides. Some authorities use the lower astronomical tide (LAT) as the reference data point.

The tidal excursion in deep seas is relatively low – usually less than 1m – however approaching continental coasts the tidal range can increase dramatically.

As mentioned above, tidal cycles produce currents. High tide has significant flow during the rising tide while ebb is the flow associated with the falling tide. Periods of low or no flow are called stagnant water.

Stagnation times do not coincide exactly with high and low water peaks as water continues to flow for some time after a peak has been reached. Tidal currents are often stratified, with the surface current flowing in a different direction from the current at a certain depth.

Conclusion

By now it should be evident that the trial-and-error method applicable to industrial production procedures cannot be applied to the unique pieces that populate the critical environment of offshore facilities. Therefore, only a design approach based on virtual prototyping and numerical simulation can analyse and evaluate the different hypothetical scenarios to ensure the required safety and robustness of offshore installations, as well as determine the most cost-effective solution for the different scenarios.

The challenges posed by the marine environment must be met with constant research, application, diligence, humility, enthusiasm, and creativity. The right mixture of these elements allows us to achieve the success here defined as the completion of a project that results in the realization of a structure, since we still need people to generate and develop ideas – even in this age when it appears that artificial intelligence might replace people.

When the right teams are assembled to thoroughly understand the scenarios and environments in which any specific offshore design is planned, there is a high probability of identifying or detecting all the critical conditions and related combinations to be considered in order to overcome the challenges.

For further information :

▶ Livio Furlan | EnginSoft

▶ e-mail : l.furlan@enginsoft.com

![[활용 예제] Using BOI Local Sizing in Fluent Watertight Workflow](/image/thumb_document_blue.jpg)

㈜태성에스엔이

㈜태성에스엔이